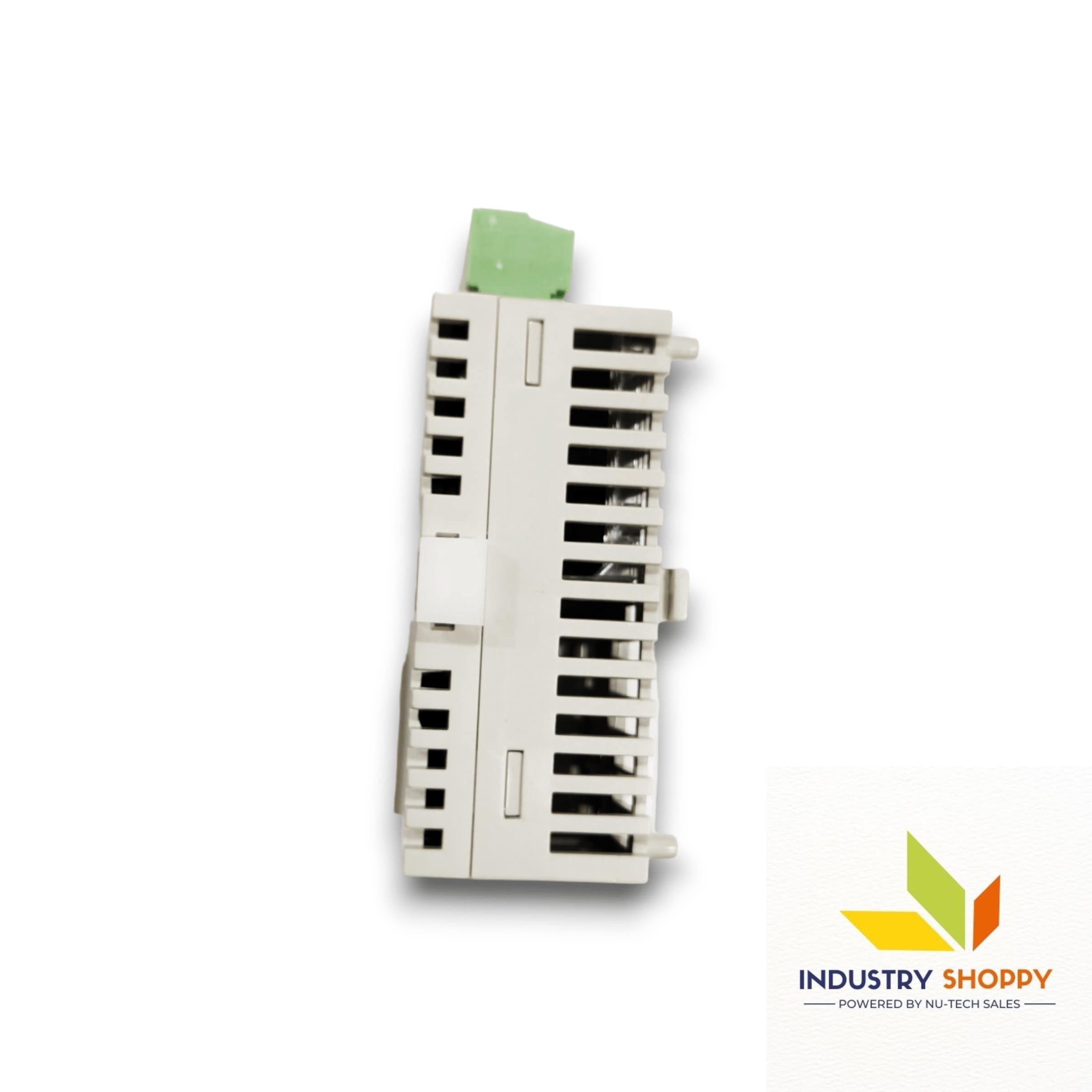

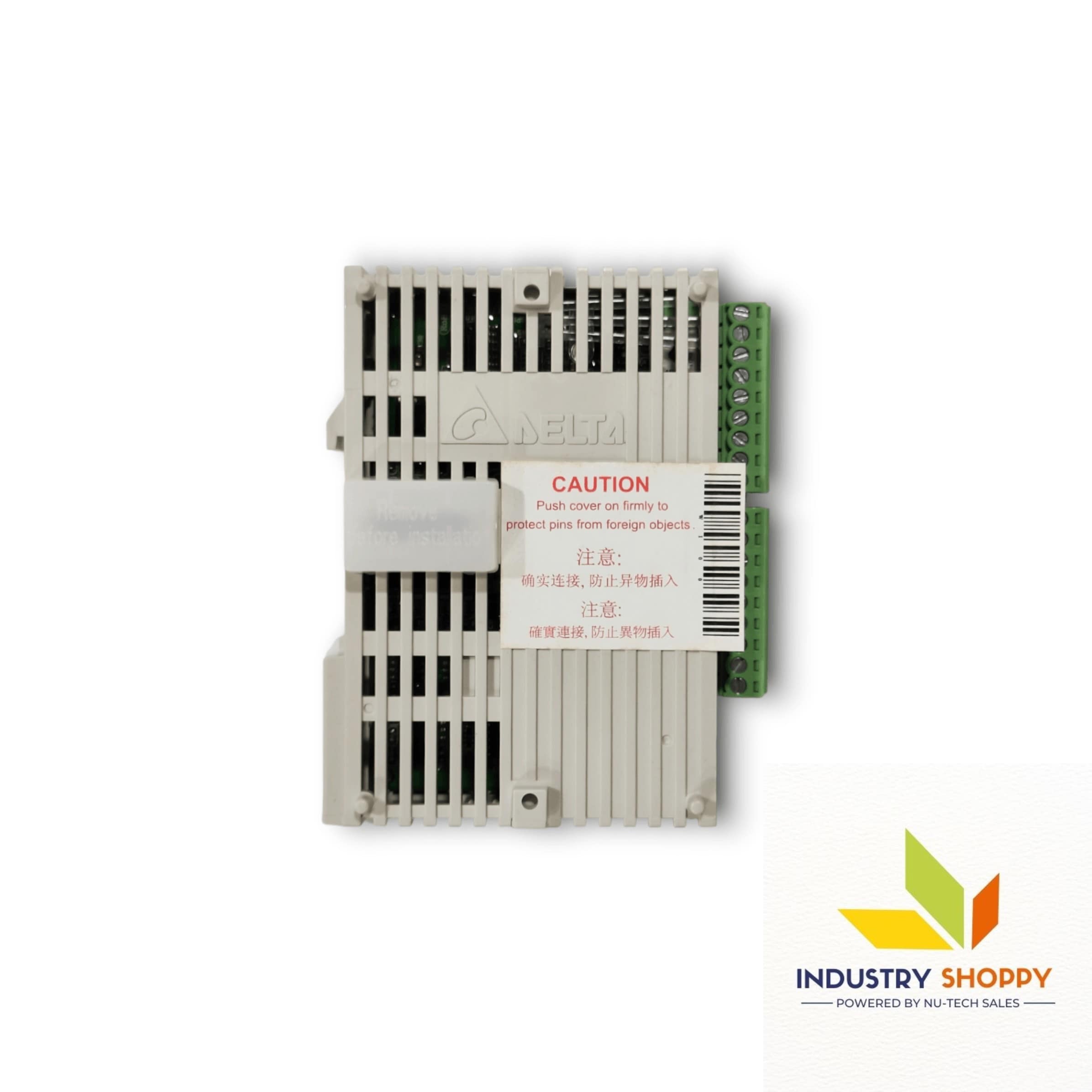

Delta DVP16SP211R PLC Module

3845 INR/Piece

Product Details:

- Frequency 50/60 Hertz (HZ)

- Features Modularity and Scalability, Robust Communication Protocols, Flexible Programming Languages, Real-time Monitoring

- Remote Control Yes

- Drive Type Electric

- Usage Industrial

- Voltage 24 VDC Volt (v)

- Product Type PLC Module

- Click to View more

X

Delta DVP16SP211R PLC Module Price And Quantity

- 100 Piece

- 3845 INR/Piece

Delta DVP16SP211R PLC Module Product Specifications

- Modularity and Scalability, Robust Communication Protocols, Flexible Programming Languages, Real-time Monitoring

- 12 Months

- 24 VDC Volt (v)

- 50/60 Hertz (HZ)

- Industrial

- Electric

- PLC Module

- Yes

Delta DVP16SP211R PLC Module Trade Information

- Paypal, Cash in Advance (CID), Cheque, Western Union

- 450 Piece Per Month

- 2 Days

Product Description

The DVP16SP211R is a model from Delta's DVP series of Programmable Logic Controllers (PLCs). Here are the key specifications and features for this PLC:

Specifications:

-

Model: DVP16SP211R

-

I/O Configuration:

- Digital Inputs: 8 inputs

- Digital Outputs: 8 relay outputs

-

Power Supply:

- Typically operates on a 24V DC power supply.

-

Processor:

- High-speed processing for fast and reliable control.

-

Program Capacity:

- Usually offers a significant amount of program steps, often measured in Ksteps (e.g., 16K steps).

-

Communication Ports:

- May include ports for RS-232, RS-485, and Ethernet communication.

-

Expansion Options:

- Supports expansion modules for additional I/O, communication, and special functions.

-

Programming Software:

- Typically programmed using Deltas WPLSoft or ISPSoft software.

-

Special Features:

- High-speed counters

- Pulse output for precise motion control

- PID control functions

- Built-in real-time clock

-

Operating Temperature:

- Designed to operate within a temperature range of 0C to 55C.

-

Mounting:

- DIN rail mounting or panel mounting options.

Applications:

- Used in industrial automation for controlling machinery, processes, and systems.

- Suitable for applications requiring precise control and reliability.

Additional Information:

- Dimensions and Weight: Check the specific datasheet for exact dimensions and weight.

- Certifications: Typically includes CE, UL, and RoHS certifications for safety and compliance.

Flexible and Modular Design

Engineered for versatile industrial environments, the DVP16SP211R PLC features a modular architecture, enabling expansion and adaptation to varied automation tasks. Its scalable configuration supports evolving operational requirements, making it suitable for both small and large manufacturing setups.

Advanced Communication Capabilities

This PLC module incorporates robust communication protocols, ensuring seamless data exchange with other automation equipment. Its real-time monitoring features provide immediate feedback and diagnostics, enhancing operational reliability and uptime.

Effortless Integration and Programming

The DVP16SP211R allows users to choose from multiple programming languages, simplifying the implementation process. Its user-friendly software interface accelerates deployment and empowers engineers to develop and modify control schemes rapidly.

FAQ's of Delta DVP16SP211R PLC Module:

Q: How can the Delta DVP16SP211R PLC Module be integrated into existing industrial systems?

A: The DVP16SP211R PLC is designed for seamless integration due to its modularity and robust communication protocols. It can be added to existing automation setups using standard interfaces and programmable connections, facilitating easy compatibility with a wide range of equipment.Q: What are the key benefits of using this PLC module in industrial automation?

A: Key benefits include its scalable design, real-time monitoring, and flexible programming support. These features enable users to customize control solutions, enhance system reliability, and adapt to changing process requirements confidently.Q: When should I consider upgrading to the DVP16SP211R for my facility?

A: It is ideal to upgrade when your current control systems require better scalability, improved communication, or enhanced monitoring capabilities. If your processes are expanding or becoming more complex, this PLC provides the flexibility and robustness needed.Q: Where are the main markets and distribution sources for the DVP16SP211R PLC Module?

A: The DVP16SP211R is widely available through various channels such as manufacturers, authorized dealers, distributors, and suppliers, especially from China. It is also supported by exporters, wholesalers, and service providers serving global industrial markets.Q: What is the process for programming and configuring the DVP16SP211R?

A: Programming is achieved through user-friendly software supporting several languages. Engineers can develop, simulate, and deploy control programs using provided development tools, with the module's architecture facilitating both quick setup and future modifications.Q: How is the DVP16SP211R PLC Module used to improve efficiency in manufacturing?

A: By enabling real-time process monitoring, robust automation, and adaptability to system changes, the DVP16SP211R helps streamline operations, reduce downtime, and optimize resource use, thereby boosting overall manufacturing efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free